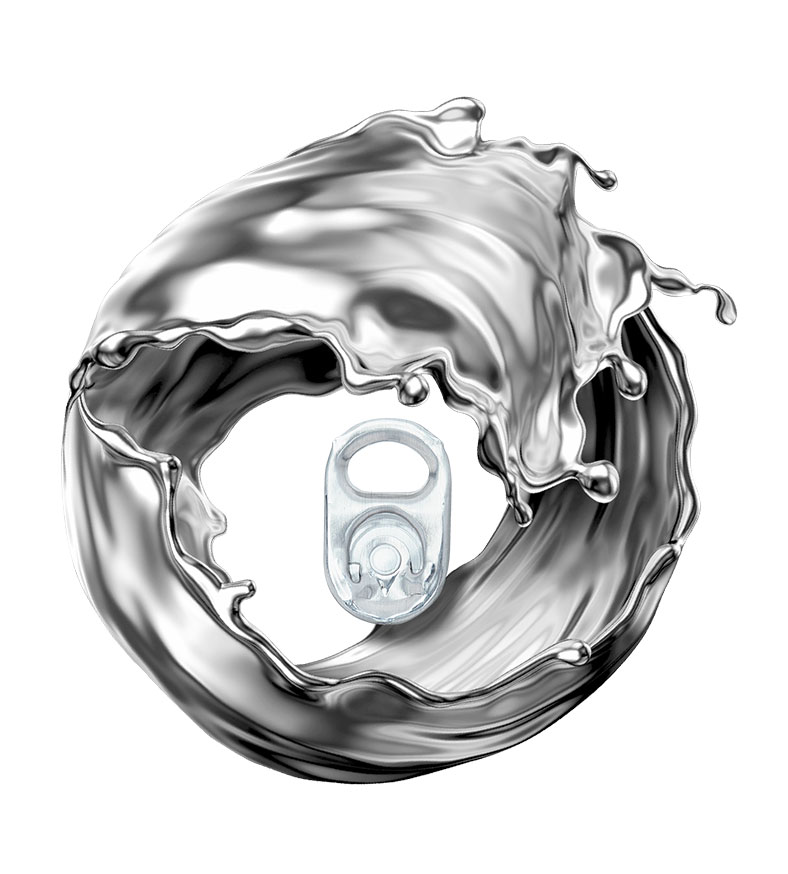

Real Circularity

Create the perfect circle for our packaging products in which materials can be in use in perpetuity.

- Align the industry to achieve a 90% global recycling rate for aluminum beverage cans, bottles and cups.

- Work together with our supply chain partners to achieve an 85% average recycled content in the aluminum used to produce beverage cans, bottles and cups in the regions where we operate.

- Launch second generation of ReAl® aerosol container technology with 75% recycled content.

Climate Leadership

Advance climate science and achieve net zero carbon emissions prior to 2050.

Resource Efficiency

Decouple growth of our business from resource use in our operations with a focus on aluminum, energy, and water use.

- 80% of global beverage can production with weight-optimized STARcan dome designs, and 50% global aerosol can production with lightweight ReAl alloy (combined, saving greenhouse gas emissions of more than 320,000 metric tons during the first five years of the 2020-2030 goal period).

- 30% energy efficiency improvement (electricity and natural gas) in can manufacturing (2020-2030).

- 50% water efficiency improvement in can manufacturing, with a minimum 30% improvement across existing facilities (2020-2030).

Responsible Sourcing

Be part of a responsible and transparent value chain to grow our business and manage our risks.

- 100% of aluminum purchased comes from certified sustainable sources.

- Strengthen Ball’s supplier diversity program and double our annual spend with diverse suppliers in the U.S. (2020 baseline: $107 million).

- Annually assess environmental, social and governance practices of all critical suppliers with an annual spend of $5 million or more, and ensure corrective actions are being implemented where suppliers fall short of Ball’s requirements.

Health, Safety & Well-Being

Every employee, contractor and visitor gets home safe every day, and employees are supported with well-being resources to promote a healthy, engaged and productive workforce.

- Reach a 1.12 Total Recordable Incident Rate, a key milestone on our

journey to create a safety culture where zero injuries is a reality (2022–2030). - Enable all employees and their families to thrive as their authentic selves by providing resources focused on their physical, mental and financial well-being.

Belonging, Inclusion & Diversity

Provide equal opportunities for career development.

- We are committed to increasing the percentage of women in leadership roles across the organization and in manufacturing roles in our plants.

- We are committed to reflecting the communities where we operate around the world in terms of race and ethnicity.

- Implement a holistic communication and training approach to drive a culture of inclusion and inclusive leadership

Talent Development

Develop a competitively skilled and capable workforce to drive our growth.

- Create and launch graduate/entry-level and intern programs across all regions with a focus on engineering and operations to build skills and a diverse pipeline of critical talent.

- 100% of manufacturing employees participate in industry-leading technical training, which will significantly shorten the time required to develop world-class can makers.

- 100% of computer-based employees in our global packaging businesses and corporate offices will leverage the Ball Learning Library, supporting the development of a competitively skilled and capable workforce.

- 100% of people leaders participate in at least one leadership development experience each year.

Employee Experience

Cultivate an employee experience in which all employees feel like they belong, can thrive and be heard.

- Develop and deploy an expanded employee feedback system and listening strategy, yielding timely and targeted data to better understand and shape the employee experience and address issues relevant to each population.

- Ensure Ball's Employee Value Proposition, including our values and what we stand for as a company, is delivered and experienced consistently around the world and evaluated through our flexible employee listening strategy.

- Reimagine Ball Networks globally to help strengthen employee connections and communities for personal and professional growth.

Community

Enrich the communities where we live and work through the Ball Foundation, corporate giving, employee giving and volunteerism.

- Enable 100% of employees to give and volunteer, and achieve a 35% participation rate globally (2025).

- Extend sustainability and STEM education program globally and expand outreach to students, teachers and facilitators by 60% (2025).

- Proactively leverage Ball products (inclusive of beverage packaging, aerosol and cups) for good and donate at least $1 million of in-kind donations (2025).