BALL'S 1.5 DEGREE SCIENCE-BASED TARGET

In 2019 we set an ambitious new target of achieving a 55% absolute reduction in greenhouse gas (GHG) emissions from our own operations by 2030, despite expectations that the business will experience unprecedented growth during this period. The target aligns with the latest climate science reported by the Intergovernmental Panel on Climate Change, a global body of climate experts which has announced that global warming should be limited to 1.5°C above pre-industrial levels if its worst impacts are to be avoided.

Our 1.5°C target was approved in early 2020 by the Science Based Target Initiative, an international governing body that independently assesses and approves companies’ GHG goals. We are the first aluminum can manufacturer to adopt a science-based target. We will aim to meet the 55% target in two main ways: by switching to renewable energy and by improving energy efficiency in our manufacturing processes.

By setting such an ambitious goal, we are striving not only to help with global efforts on climate change, but to improve Ball’s performance and to help our customers reach their own emissions reduction targets – which rely heavily on the carbon footprint of our aluminum cans. Providing support for our customers in this way provides us with a commercial advantage and is a key example of how sustainability supports the strategy that drives our business.

We began to transform the way we embed climate change throughout our business in 2019 with our first internal Climate Summit. Sixty leaders from across the company gathered to generate and commit to actions that will meet our ambitious targets and prepare the company for a transition to a low-carbon economy. Climate Summit discussions focused on four key concepts: 1) embedding the cost of carbon; 2) transformative process innovation; 3) igniting ownership; and 4) addressing value chain emissions.

VALUE CHAIN TARGET

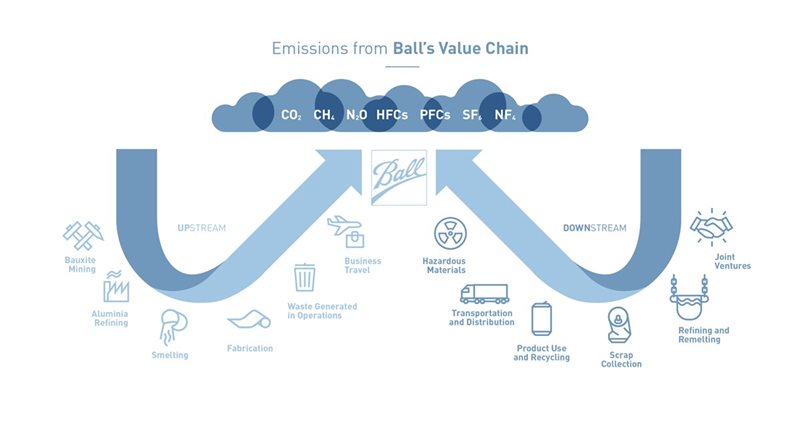

As part of our science-based target, we will aim to cut greenhouse gas emissions 16% across our value chain by 2030.

Around 80% of the GHG emissions associated with our products come from within our value chain rather than our own operations. We collaborate with our value chain partners to make a difference in this area, both ‘upstream’ in the products and services we purchase from suppliers, and ‘downstream’ in the way our products are collected, sorted and recycled.

We are able, for instance, to work with various stakeholders to cut GHG emissions by increasing recycling rates (as we explain in our Real Circularity webpage), and we can also help to reduce downstream emissions (such as through transportation) by lightweighting our cans.