Our Circularity Vision

Our goal is to advance this vision by actively advocating for policies and actions that move us toward a circular economy—one in which materials are not just used and thrown away, but are reused and recycled endlessly.

Reaching Real Circularity

"At Ball, we strive to create the perfect circle for our packaging products so that the materials can be used over and over. We are striving toward our 2030 commitments."

-

Align the industry to achieve a 90% global recycling rate for aluminum beverage cans, bottles and cups (2030).

-

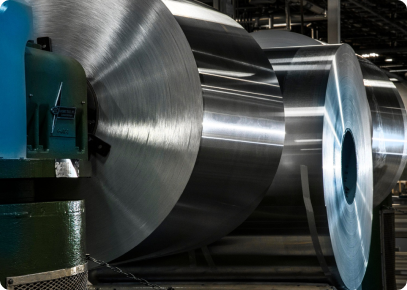

Work together with our supply chain partners to achieve an 85% average recycled content in the aluminum used to produce beverage cans, bottles and cups in the regions where we operate (2030).

-

Launch second generation of ReAl® aerosol container technology with 75% recycled content (2030).

Daniel W. Fisher

Our environment and the future of our planet depend on it.

Facts About Recycling

Aluminum cans are the world's most recycled beverage packaging.

Aluminum cans, bottles and cups are easily recyclable regardless of size, color or format with no material degradation.

Aluminum maintains a high value once relcycled. Recycling aluminum has the potential to save billions of dollars' worth of materials currently lost to landfills.

Recycling aluminum reduces greenhouse gas emissions by replacing virgin materials.

Policy Matters: In certain geographies, programs like Deposit Return Systems and Extended Producer Responsibility boost recycling rates and quality.

Real Circularity

50 States of Recycling

Why ASI Matters

Ball is the first aluminum can maker with both ASI certifications. Find out how sourcing find out how sourcing ASI certified aluminum helps make society more sustainable and strengthen brands that are part of this process.

Increasing the use of recycled content in our products represents our biggest decarbonization lever. Manufacturing with recycled aluminum is 20 times less energy intensive, which means the carbon intensity of aluminum packaging falls precipitously as the percentage of recycled content used increases.