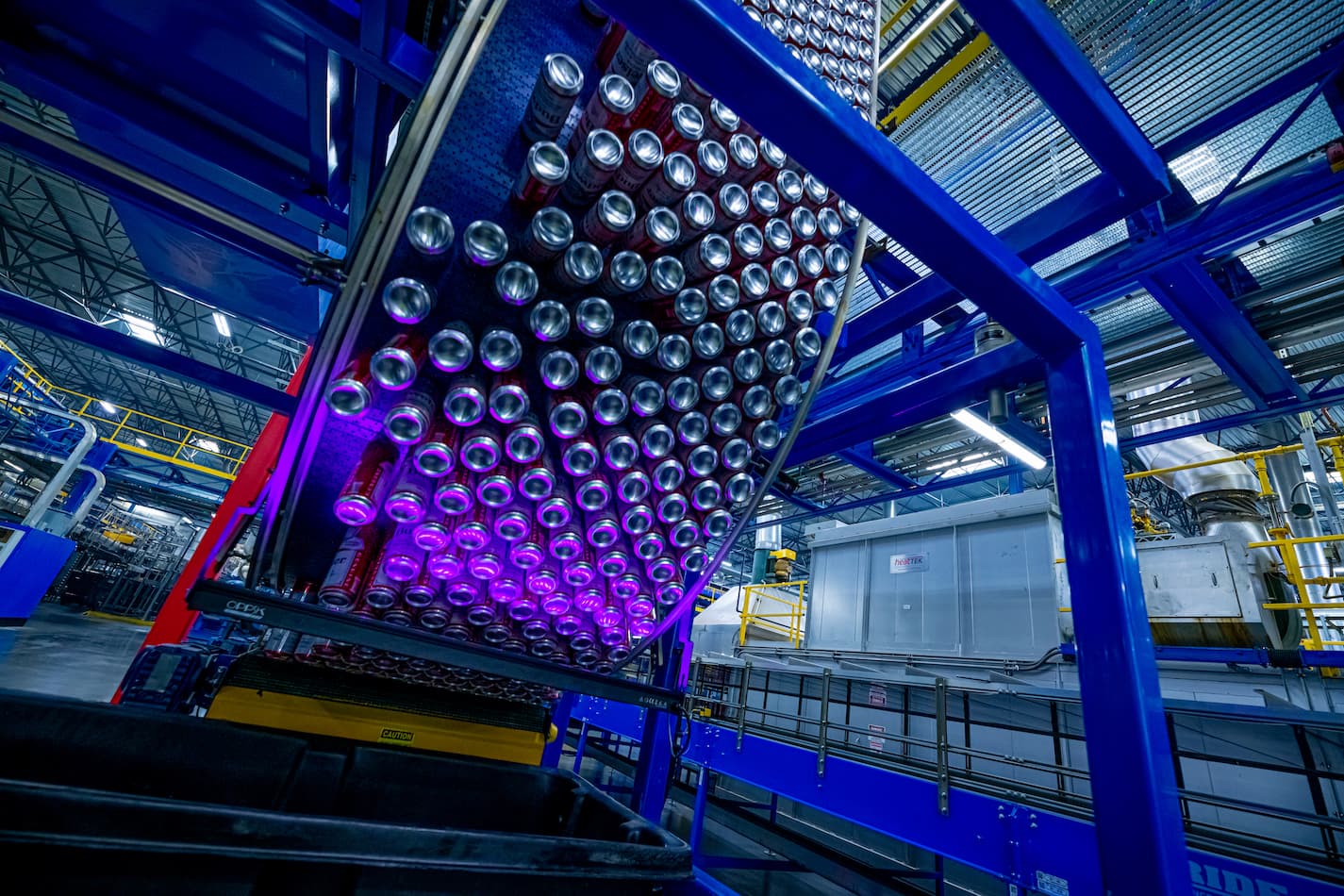

Quality, sustainability and service—at every step

Choose Ball to launch your brand’s circular economy.

Ball leads in aluminum packaging because we defy the status quo with creative can and bottle designs based on sustainable manufacturing principles. Building on 140 years of packaging innovation, Ball has launched a global collaboration with beverage customers and consumers to build a circular economy.1 Together, we reuse materials instead of throwing them away after a single use. The work is essential to the future of human prosperity and the basis of brand loyalty among climate-conscious consumers.

1. Ball embraces the definition of a circular economy provided by the Organization for Economic Co-operation and Development (OECD) described in The Circular Economy: What, Why, How and Where.

Ideas in action

The shape of the future is available today.

The future arrives every day for our customers, with new competitors eager to compete for shelf space. Ball gives you the tools to meet those challenges with innovative designs that champion style with sustainability. With Ball on your team, recyclable packaging doesn't come at the expense of striking design, fresh flavor and quality drinking experiences. We can set your brand apart from the competition.

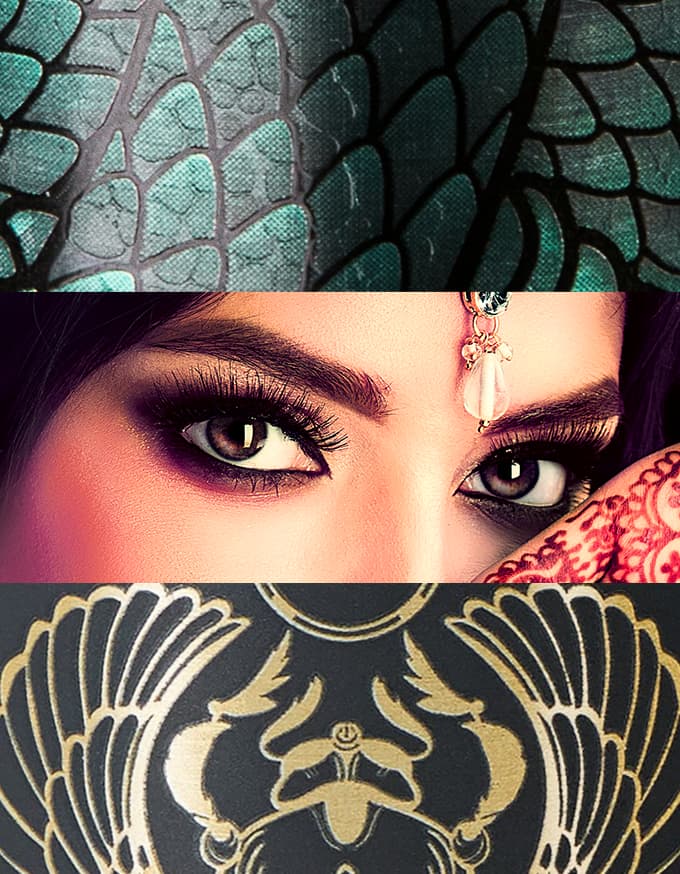

Graphics & Design

Stand out with Ball graphics.

The beverage industry offers consumers more choices every year. Ball keeps your brand at the forefront of customer experience. Great graphics capture shoppers’ attention and help your product stand out on crowded retail shelves. Our unique printing technologies capture and keep consumer attention with phenomenal visual and tactile experiences. We offer specialty inks, textured overvarnishes, customizable tab types, scannable codes and colored ends.

Ball special effects let you turn the most imaginative product design into a striking on-shelf reality. Don’t know where to begin? Start by letting our graphic design experts share resources to guide you through the process.

Marketing services

Our extra boost for your business.

Whether you’re an established beverage line or just starting out, our marketing teams can help your brand flourish. Ball was the first to brand food storage and has remained a household name since the 1880s. That kind of longevity doesn’t happen without constant consumer research and innovation to help our customers lead in new market trends and technologies. No matter the type of beverage, no matter the branding challenge, our consumer insights team can help you scale your product portfolio, create unique drinking experiences that build customer loyalty. Are you ready to stand out from the competition?

Technical Services

Because technology should make life easier.

Ball’s passion for innovation helped make us the largest supplier of beverage cans in the world. We embrace technology to deliver a better product for a healthy planet. Our Alumi-Tek® bottle, Crowler Can®, and Widget Inside® technologies are just three examples of how Ball ensures that consumers experience each sip exactly the way you intend while reducing reliance on raw materials and improving the recyclability of the packaging.

Our dedicated technical support teams have the expertise in consumer insights to answer all your questions. We believe in passing our technical knowledge along to our customers because sustainability is an industry-wide mission.

Discover Ball

Ball started with a family and grew into a global community. Meet the Ball brothers and discover how their dream reshaped the world.

Committed to sustainability

By 2030, we’ll slash emissions, recycle 90 percent of the aluminum we use, and buy only sustainable materials.

Join Ball Packaging

Join us on our journey to provide the most sustainable packaging solutions for our customers.