On our path to Net Zero prior to 2050, we will reduce our absolute carbon emissions from our own operations by 55% by 2030, against a 2017 baseline.

In 2021, Ball Corporation emitted 911,576 metric tons of GHG emissions from our direct operations (Scope 1 and 2), 24% less than in 2017. Forty-eight percent of our GHG emissions resulted from our electricity consumption (Scope 2), and 51% came from stationary combustion (Scope 1).

Scope 1 emissions are direct GHG emissions from sources owned or controlled by Ball, and primarily include emissions from fossil fuels, such as natural gas and diesel, burned on site.

Scope 2 emissions are indirect GHG emissions from the generation of electricity, heating, cooling and steam generated off site and purchased by Ball.

In order to meet our science-based target in the face of unprecedented growth, Ball has set two critical goals that must be achieved in order to reduce our absolute emissions by 55% by 2030:

- Achieve 100% renewable electricity globally by 2030, with an interim target of 75% by 2025.

- Achieve 30% energy efficiency improvement (electricity and natural gas) in can manufacturing (2020-2030).

100% Renewable Electricity by 2030

Achieving 100% renewable electricity globally by 2030 is a pivotal step in achieving our Science-Based Target. We’ve also set an interim target of achieving 75% renewable electricity globally by 2025 to showcase our rapid decarbonization efforts in our largest markets. Renewable energy is not only critical to Ball’s carbon footprint but is also an important component to reducing the carbon footprint of our packaging. In our Life Cycle Analysis work, we have demonstrated that use of 100% renewable electricity can reduce the carbon footprint of an aluminum beverage can between 10 and 18%, depending on the region of manufacturing and type and size of the package.

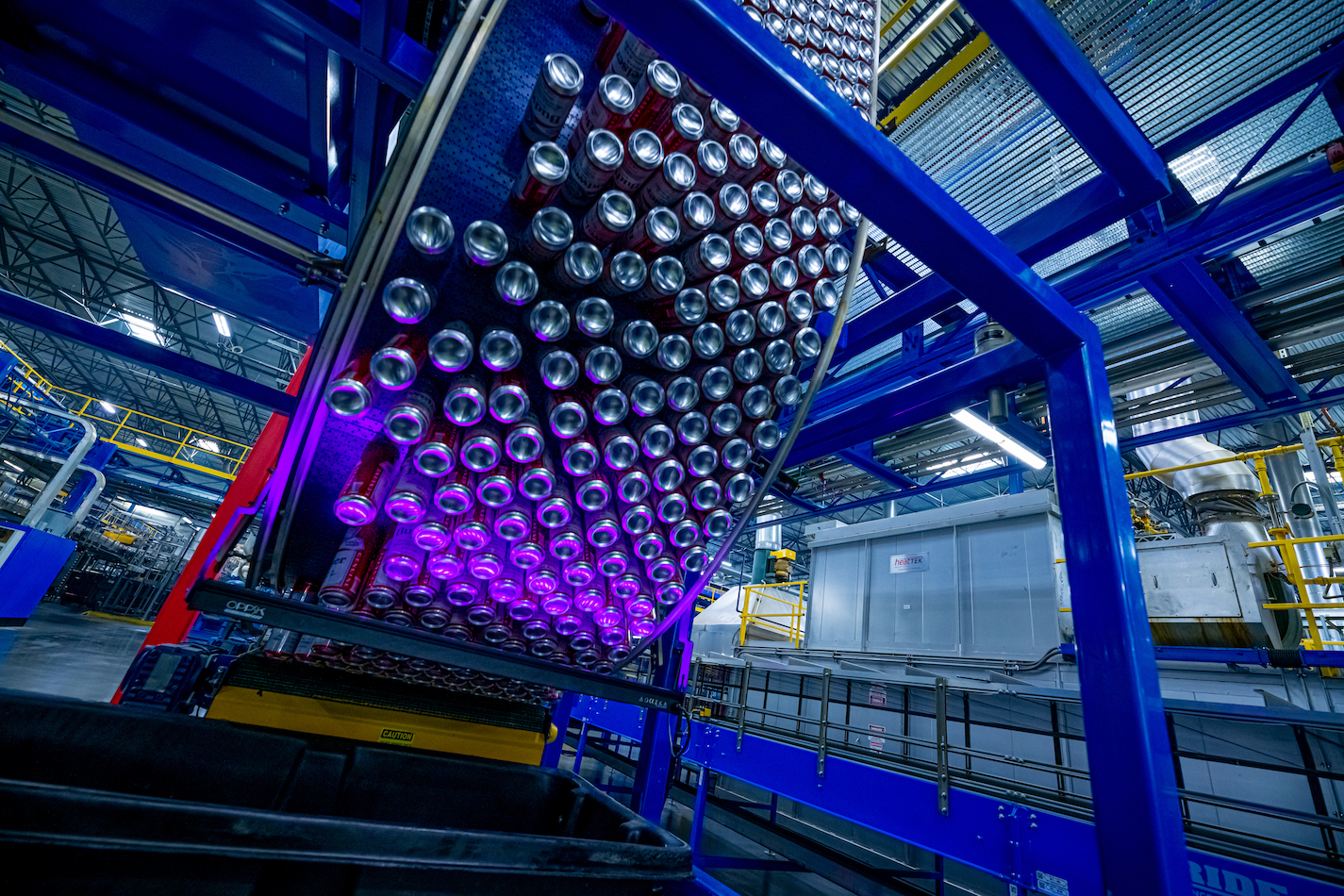

To drive progress towards this goal, Ball has executed five virtual power purchase agreements (VPPAs) – four wind and one solar – for 497 megawatts (MW) of new renewable energy in North America and Europe. While one wind and one solar project still remain in development, 254 MW of new wind projects reached commercial operation in 2021 and began producing renewable electricity. Once all five projects are operational, they are expected to cover approximately 65% of Ball’s global electricity demand.

With the electricity produced from these wind projects, contractual Renewable Energy Credits (RECs), and additional guarantees of origin (GOs) purchased and retired in Europe, Ball sourced 44% of its global electricity demand in 2021 from renewables, making considerable progress on our 2025 and 2030 renewable energy goals. These efforts allowed us to reduce approximately 390,392 metric tons of GHG emissions year-over-year in 2021.

To meet the electricity demand of our growing businesses as well as efforts to electrify thermal energy needs and eliminate the use of natural gas, we continue to negotiate additional VPPAs and also diversify our renewable energy strategy. Our energy procurement team evaluates direct supply opportunities with our utility partners and evaluates the potential for on-site renewable energy production in new as well as existing facilities. Our strategy centers on fostering the development of new, additional renewable energy capacity while using the purchase of unbundled RECS/GOs to meet regional goals and the needs of our customers in the immediate term.

In order to drive resource efficiency and cost reduction, as well as limit our needs for additional renewable electricity, energy efficiency also remains a key component of our strategy.

30% Energy Efficiency by 2030

We are committed to reducing the amount of energy required to produce each beverage can in our manufacturing plants by 30% during this decade. This primarily means cutting back on our use of electricity and natural gas. Since our Global Beverage Packaging business accounts for most of our energy consumption – 89% of our total of 4.8 million megawatt hours in 2021 – much of our efforts are focused in this business. Given we have plans in place to eliminate all GHG emissions associated with electricity by 2030 through the use of 100% renewable electricity, our attention is now on reducing the use of natural gas.

While our existing plants implemented a number of energy efficiency projects during 2021, the energy efficiency of our beverage can manufacturing remained flat year over year. This was driven by the opening of four new plants and multiple line additions that come with lower efficiencies during the first few months of operation.

Opposing trends, such as increases in can sizes, shapes and labels, line or plant curtailments, and new line startups, often offset progress toward our energy efficiency goals. Our efficiency decreases as manufacturing line stoppages increase due to reduced demand or we experience a greater number of height, diameter or label changes. In particular, our beverage packaging business continues to experience a decline of standard can sizes, growth of our specialty can business and shorter production runs. To manage these challenges effectively, we invest in our businesses and expect additional energy performance gains in 2022 and beyond.

Our Approach

Every Ball plant commits to annual energy goals supported by detailed action plans. Real-time energy information systems provide visibility into our operations at the equipment level so we can better understand, manage, report on and benchmark the performance of energy-consuming processes. All of Ball plants have formal energy management systems at year-end 2020.

To significantly and cost effectively reduce our energy consumption, we follow a global energy strategy that addresses energy supply and demand and requires the consideration of energy efficiency when making investment decisions.

To further accelerate our progress, in 2021 we continued to invest in energy monitoring across our global network of beverage can manufacturing plants. In order for Ball to harness the power of this data, we began implementing a software solution with Artificial Intelligence (AI) to make predictive, accurate, and actionable decisions to optimize our roadmap on reducing energy and water use, carbon emissions and utility costs. This system will not only provide our plant operators with real-time insights into improving energy efficiency on a day-to-day basis, but will allow our regional engineering and operations teams to optimize future investments while meeting our sustainability goals.

We have also began exploring the potential for electrification of ovens used in our can making process that traditionally use natural gas – including working with key suppliers to begin testing electric heating options at our innovation center in Colorado. Through electrification of thermal energy loads and the use of renewable electricity, there is great potential to reduce fossil fuel use and Scope 1 GHG emissions. However, this can increase our demand for electricity which further informs our projections for renewable energy needs.

MACHINERY AND EQUIPMENT

The majority of our energy consumption comes from air compressors and ovens in our plants. In a beverage can plant, air compressors consume between 20% and 30% of the electricity. We conduct audits of our compressed air systems and optimize performance by reducing system pressure, minimizing wasteful air use and leaks, and decreasing manufacturing equipment demand. We continued to install more efficient compressors and connected additional equipment to low-pressure systems during the reporting period. At the end of 2019, 59% of our beverage can plants operated dual-air systems that supply equipment with either high- or low-pressure air. Compared to traditional systems that rely only on high pressure, low pressure compressed air is 22% more energy efficient than high pressure air, and also results in less energy loss through artificial demand. In 2019 a global team of regional staff developed a compressed air global standard for new construction projects to ensure future energy efficiency.

Below are a few examples of 2020 energy efficiency efforts: In 2020, air compressor replacements in our Gelsenkirchen, Germany plant and Nogara, Italy plant will save a combined 4,000 megawatt hours of electricity annually. Our Williamsburg, U.S., plant completed an air compressor audit in 2020 which resulted in several action items whose fixes resulted in nearly 900 megawatt hours of electricity savings.

Within our operations, ovens are used to evaporate water from cans after being washed and to cure external and internal coatings. Ovens account for up to 75% of a beverage can plant’s natural gas usage and up to 20% of its electricity usage. Through oven audits, low-cost optimization projects, and increased employee awareness of oven energy use and associated costs, we have realized natural gas efficiency gains in our can businesses of 4.7% between 2015 and 2020. A 2020 burner replacement program in our Buenos Aires, Argentina, Três Rios, Santa Cruz and Recife, Brazil can plants led to a combined annual savings of 4,730 MMBtu, equal to approximately 1,386 megawatt hours.

HEATING AND COOLING

Heating, ventilation and air conditioning (HVAC) control during the heating season is another energy efficiency opportunity. Central control systems and higher awareness of HVAC-related energy usage and costs are driving progress. We identify optimal temperatures for different areas within a plant and educate employees on how they can achieve these temperatures with the lowest energy input. Installing heat curtains, for example, reduces heat or cooling loss.

LIGHTING

During the reporting period, lighting continued to be a priority for our energy engineers. While it is crucial to provide proper lighting to keep our employees safe and allow them to effectively execute their jobs, lights do not need to be continually at full power. Every Ball plant changed some lighting to LED and several underwent complete conversions. We include adaptive lighting control options to further increase efficiency by matching the light levels to occupancy and daylight availability. Compared to conventional lighting, a completely converted LED plant with both lights and respective controls saves about 75% lighting electricity, with 55% of this savings from the LED and 45% from the controls. In addition to LED lighting, we are installing skylights and additional windows in some of our facilities to better utilize daylight.

EMPLOYEE AWARENESS AND ENGAGEMENT

A team effort is required to achieve our plant energy reduction goals. That is why several facilities established formal voluntary energy conservation or broader sustainability teams. Ball's metal beverage packaging plant in Fort Atkinson, Wisconsin, has a multi-year track record of engaging its employees in energy conservation efforts and improving energy efficiency. Between 2010 and 2021, the plant improved its electricity efficiency by 20%. And the team in Fort Atkinson continues to develop and test new ideas to further maximize the value of our existing businesses.

COMMITTED AT ALL LEVELS

Ball’s management team is committed to energy improvements and invested $7.8 million in energy-saving projects in 2020. These measures will generate estimated electricity savings of 34.2 million kilowatt hours and natural gas savings of approximately 23.1 million kilowatt hours per year, exceeding the annual energy consumption of over 5,000 average U.S. households.